Description

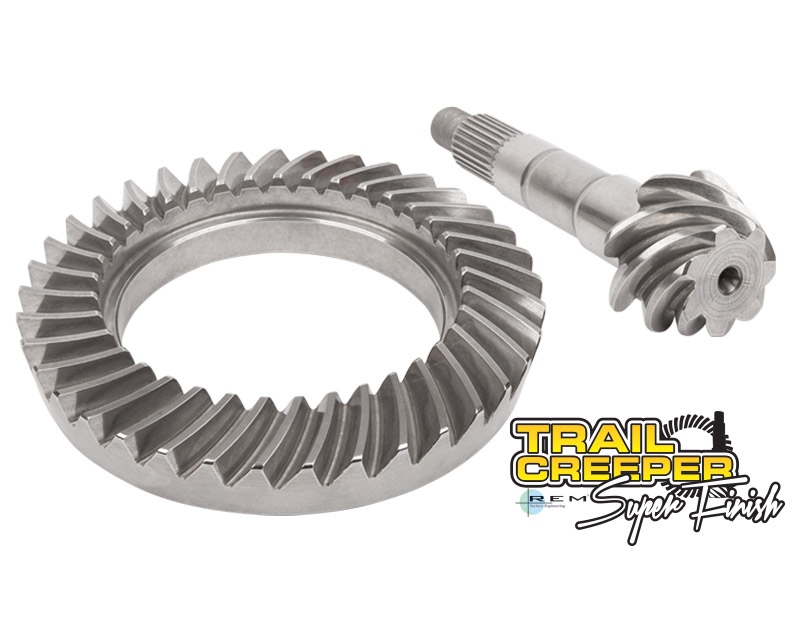

Tired of waiting for your ring and pinions to break-in before towing or hitting the trail? Trail-Gear has your solution with our new Trail-Creeper™ Super Finish Ring & Pinion Gears. Our Trail-Creeper™ Super Finish Ring & Pinion Gears require absolutely no break-in time. You can install these gears and get right into the action without the need to worry about premature ring and pinion failure.

Trail-Creeper™ Super Finish Ring & Pinion Gears are made from tool-grade 8620 steel and heat-treated for maximum strength and wear resistance. The gear teeth are cut using Gleason CNC hobbing machines & cutters. Gleason gear-cutting technology produces an unprecedented level of accuracy and surface finish, which allows the gears to transmit more torque and improve fuel efficiency.

Key Benefits:

- No break-in period

- Less friction

- Reduced wear allowing bearings and gears to last longer

Trail-Creeper™ Super Finish Ring & Pinion Gears are treated with REM® Isotropic Super Finishing (ISF®) process. The process that is used to polish our gears is the same used for aerospace applications. The REM® Isotropic Super Finishing (ISF ®) process removes the microscopic peaks in the material and creates a surface on the ring and pinion gears with a roughness of less than 10 µin Ra! This means that there is less friction between the gears, reducing wear by 95% and allowing the gears and bearings to run cooler and last longer.

The REM® Isotropic Super Finishing (ISF®) process not only decreases friction and wear in the gears, but it creates a non-directional surface that increases lubricant retention on the gear surface, reducing lubrication requirements.